Executive & Strategy

FactoryKPI Executive

KPI Dashboard with Multi-plant analytics and comparisons

Problem Solving

SolvoNext-PDCA

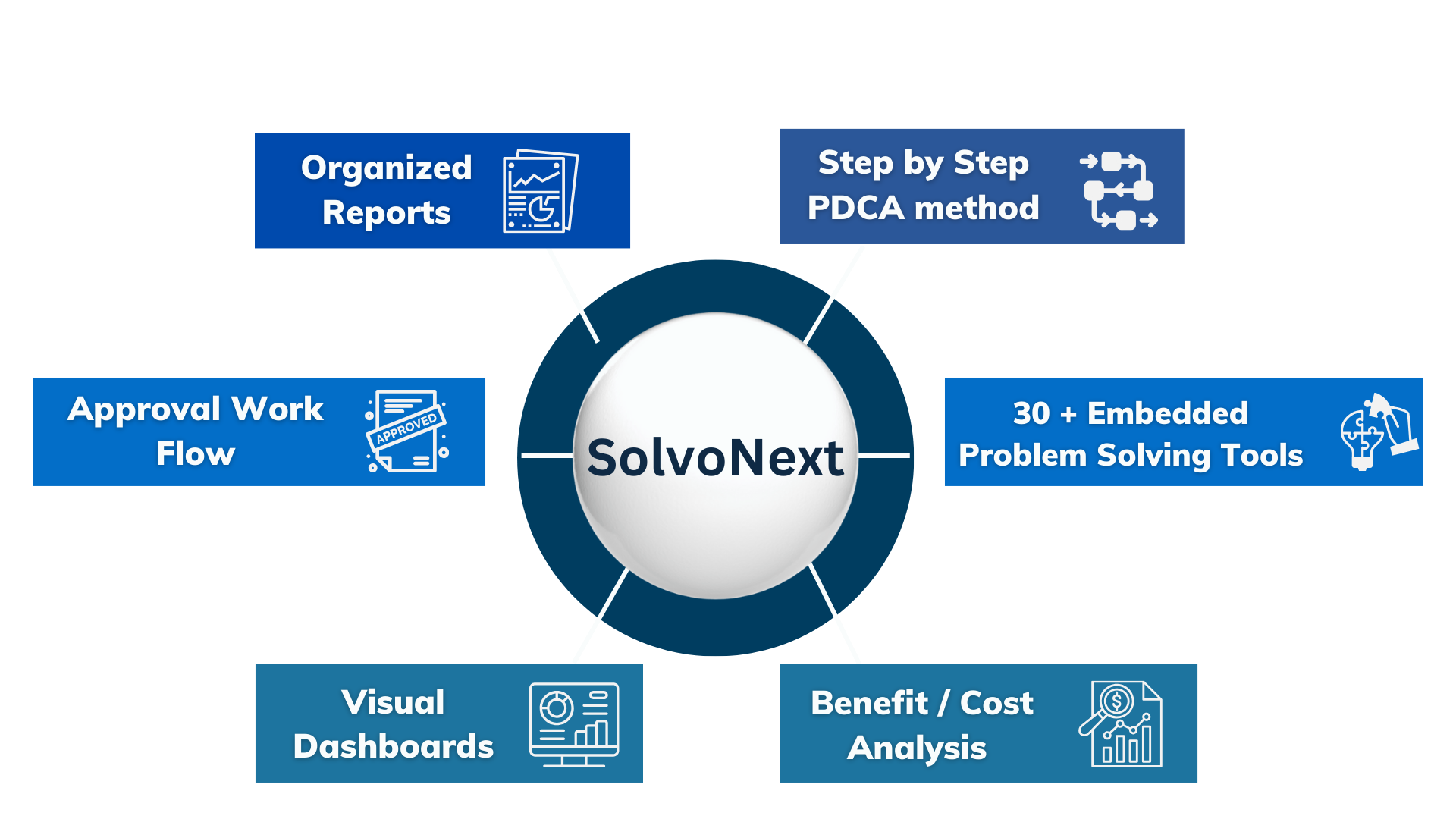

A Smarter Problem Solving and Project Management Software based on deming and Toyota's PDCA - Plan, Do, Check, Act Method.

Qualitygram

A Unique Mobile and Web Software that helps Manage and Solve Problems Faster with Improved Team Communication.

SolvoNext-NCR CAPA

Digitize your NCR & CAPA process and Reduce Cost of Poor Quality (COPQ).

Solvonext

A Smarter Manufacturing Problem-Solving Software built on Deming & Toyota’s PDCA for streamlined project management.

SolvoNext - PDCA helps your cross functional teams of engineers, shop floor personnel, suppliers and managers to collaborate and solve problems together.

Enable your Problem Solving Teams with Standard Structure and Method to Follow.

Organizations that have an established problem solving structure, have a much better chance of success in achieving their business goals. It helps the teams follow a set method of problem solving and reduce human error in manual processes. For Example for many years Toyota has used the PDCA method, companies like GE and Caterpillar have used Six Sigma method, Ford has used 8D Problem Solving.

Solvonext is based on the Toyota PDCA cycle established by Walter Shewhart, popularized by Edwards Deming and perfected by Toyota. Each step of PDCA Plan, Do, Check, Act has multiple steps such as Define the problem, Measure, Root Cause and so on. The program comes with embedded problem solving tools to empower shop floor operators.

A Smarter Way for Cross Functional Teams to Collaborate and Solve Problems - All in one place

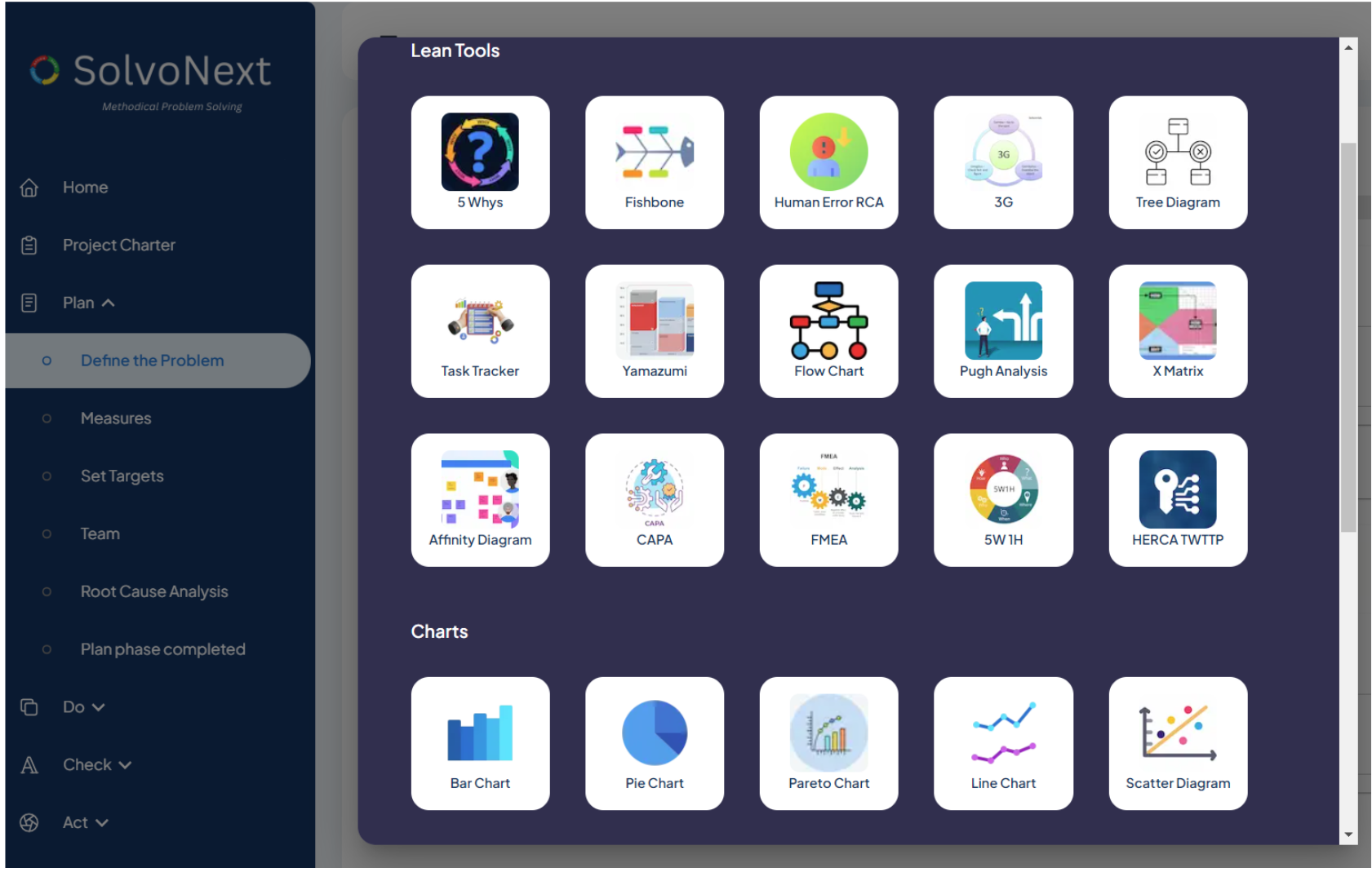

30+ Problem Solving Tools embedded, recommended by each phase

Solvonext is a lean problem solving software for factories that comes with an advanced tool box of more than 30 tools which include the 7 QC tools from ASQ, several charts and graphs, Human Error Analysis tools, Lean Manufacturing tools, Six Sigma tools, and several charts and graphs. It also allows the users to upload their own attachments and files, as you solve problems and want to exchange important information related to the project.

A problem solving team can now keep everything in one place, use the right tools for the right purpose and collaborate in a single environment for faster and more effective results. No more complexities of multiple files, emails and loss of information or knowledge.

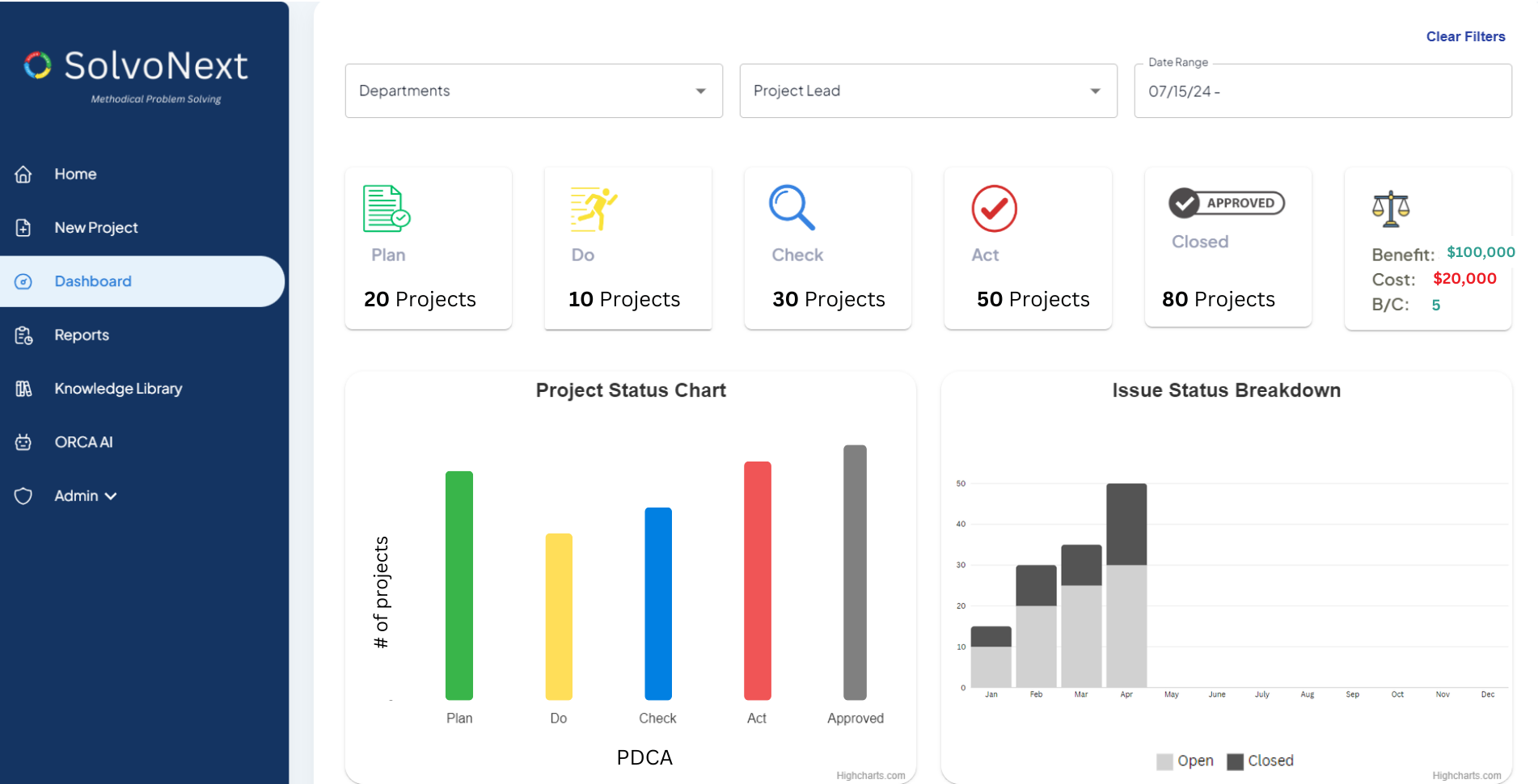

Visual Dashboards & Reports to Keep your team on Track

Solvonext makes it easy for the managers and entire team to reduce human error by tracking progress with our fully Automated dashboards and reports. Use the advanced filters to classify the data and download reports. Analyze the Benefit to Cost by departments, individuals and by projects.

Organizations which use a structured problem solving approach, give a higher importance to keeping everyone engaged with facts and figures, while recognizing their top performing employees and motivating the ones that need improvement to finish more projects.

Solvonext is built on a proven Toyota PDCA method of problem solving that works in the Real World

Methodical Problem Solving

Use the recommended Tools for each step, select from 30+ embedded lean problem solving tools or upload your own files. Keep everything in one place.

Engage Cross Functional Teams

Select Project lead, Project team members and invite them to collaborate on a project. Upload pictures, videos, drawings and communicate in one place so everyone remains engaged and informed.

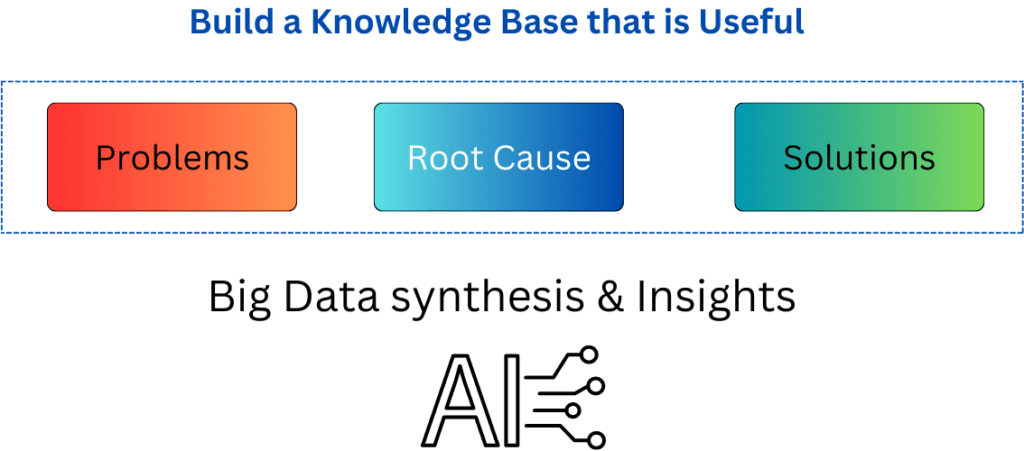

Acquire and use the Knowledge

Retain the problem solving knowledge, root cause and action items. Use this knowledge in future for repeat issues or similar issues. Use this knowledge for future launches and preventive measures.

Team Communication

Solvonext facilitates seamless collaboration by providing a centralized platform where team members can easily share updates, track progress, get approvals and communicate in real-time. This integrated communication feature ensures that everyone stays informed and aligned, leading to more efficient problem-solving in factories and improved project outcomes.

Discipline & Culture

When expectations are well set about the pace and depth of problem solving required and progress is tracked, team members automatically develop a discipline and culture. Solvonext enables your team to follow standardized approaches with PDCA steps and Tools, and steadily build a culture of problem solving within your organization.

True Root Cause

Problem Solving is only complete when Root Causes are eliminated for good. Solvonext helps your team use a variety of root cause analysis tools and even better, your entire team can see it live, collaborate and contribute to uncovering the smallest of missed details.

Improve KPI ( Key Performance Indicators ) while Developing your People

Problem Solving is directly proportional to KPI Improvement. Solvonext helps your team uncover and solve for the true root cause, and this automatically improves metrics for Quality, Safety, Throughput as well as the team's morale. The best way to Develop People and train blue-collar workers is by completing projects with success. Solvonext organically helps you create better problem solvers for your organization.

A3 Mode for Simpler Kaizens or Projects

Engage your Shop Floor Teams in Digital Kaizen and Continuous Improvement Activities by using the A3 mode. Instead of paper or whiteboards use the simple A3 mode and preserve the knowledge of root cause and solutions. They can even scan a paper copy and we will convert that to a digital format so you can keep the records for future use.

Artificial Intelligence

Our lean manufacturing software is at the forefront of AI integration, leveraging advanced technologies such as Large Language Models (LLMs) and Natural Language Processing (NLP) to transform how data is interacted with and analyzed on the shop floor. With optional AI capabilities, users can input data and soon engage in natural language conversations with our software. This AI-driven interface supports real-time querying and deep analysis, providing tailored insights through an intuitive, conversational user experience.

Our Problem Solving Software plays a crucial role in capturing and analyzing experience based knowledge from retiring employees, preserving essential insights and techniques. This structured knowledge is then made accessible to new staff, ensuring continuity and maintaining operational excellence as workforce demographics evolve. Choose our AI-enhanced manufacturing software for a safe, reliable, and insightful addition to your operational toolkit, ensuring that your shop floor remains innovative and competitive.

Pricing

Standard

Get a quote

Standard plan includes an advanced web software for your company.

Get a demoFeatures:

- Web application secured access

- Mobile responsiveness

- Detailed PDCA module

- Simple A3 module

- 30+ embedded problem solving tools

- Visual Dashboard & Tracking

- Reports

- Approval Flow

- Benefit / Cost ratios

- Email notifications and Alerts

- Role based access control

- Knowledge Library

- High Security protocols

AI (Artificial Intelligence)

Get a quote

Standard features plus Artificial Intelligence large language model integrated for insights and analysis.

Get a demoFeatures:

- All Standard Features included.

- Data synthesis and analysis with AI.

- Chat with AI and ask any questions regarding the data, comments or any information you have saved in SolvoNext - PDCA for your plant.

- Build a knowledge library of root cause and corrective actions.

Customized / Enterprise

Get a quote

Customized version as per your needs and specific plant use case. Enterprise deployment as per your requirements.

Get a demoFeatures:

- Customized Features.

- Customized deployment - your on premise server or your preferred company cloud, or a hybrid model.

- We work with you to understand your objectives, design and develop the software as per your needs.

- Talk to us about enterprise solution, for multiple plants / locations / changes in user management or any other requirements.

Choose the Deployment Options based on your Company Policies

ORCA LEAN Standard AWS Deployment

Deploy in your Company's On Premise Server

Deployment in your Company's Cloud

We understand and respect the fact that every plant has different challenges, organizational structure and culture. We will work with you to understand your requirements and customize our smart factory software solutions to best fit your needs. It is our goal to help you in your improvement initiatives for successful results.

Software Solutions for Manufacturing Excellence

Company

Social

Our Contact Info:

Email: contact@orcalean.com

Phone Number: 248 938 0375

Our Offices