Executive & Strategy

FactoryKPI Executive

KPI Dashboard with Multi-plant analytics and comparisons

Problem Solving

SolvoNext-PDCA

A Smarter Problem Solving and Project Management Software based on deming and Toyota's PDCA - Plan, Do, Check, Act Method.

Qualitygram

A Unique Mobile and Web Software that helps Manage and Solve Problems Faster with Improved Team Communication.

SolvoNext-NCR CAPA

Digitize your NCR & CAPA process and Reduce Cost of Poor Quality (COPQ).

FactoryKPI

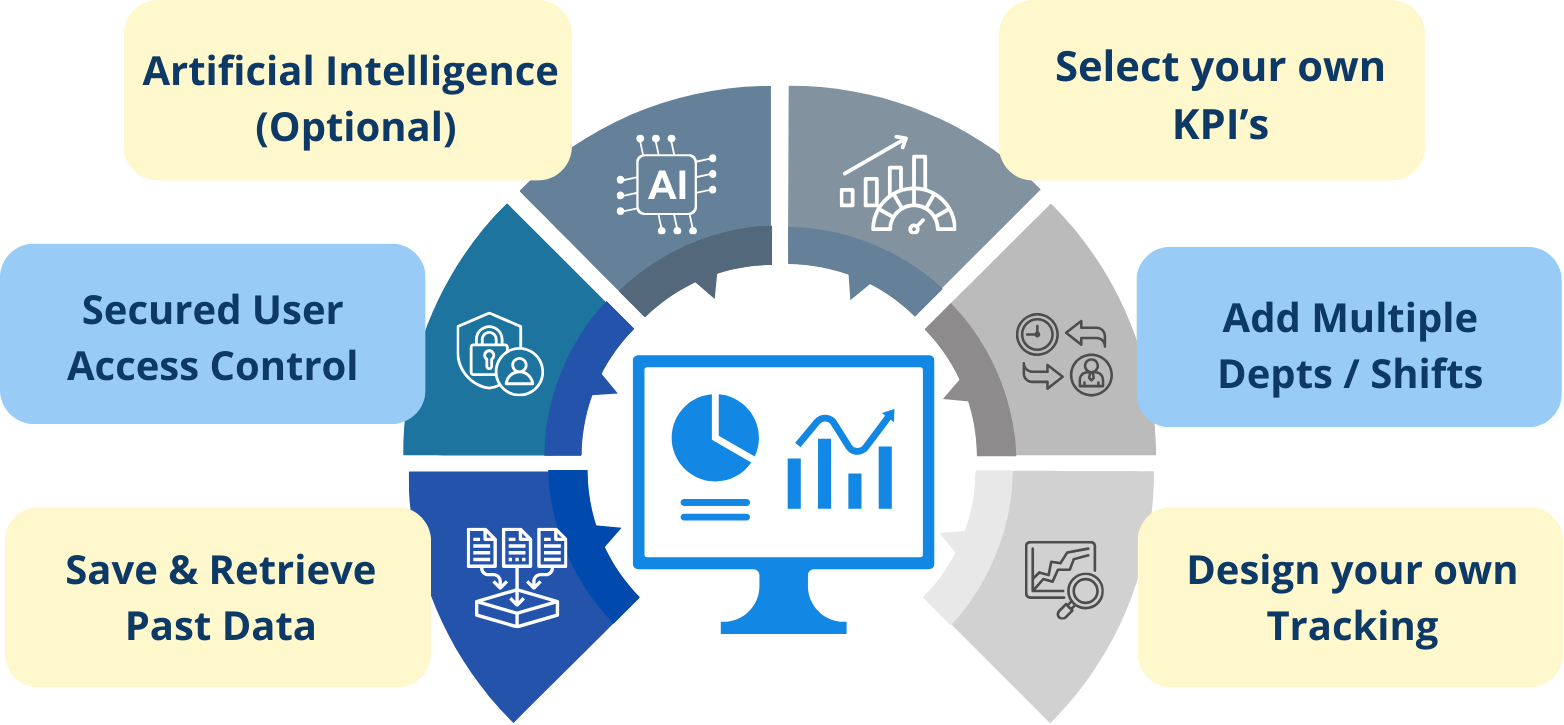

A Daily Improvement Manufacturing Dashboard for “SQDC” with optional AI integration

Track daily plant performance across Safety, Quality, Delivery, and other KPIs. Empower shop floor teams with real-time visual dashboards that streamline daily manufacturing operations.

A Powerful Visual for the Shop Floor & Daily Progress

The purpose of Factory KPI is daily improvement in factory KPIs (key performance indicators). A straightforward effective tool for the Plant managers, Operations Managers and the entire team to quickly know which kpi needs higher focus for the month and what are the top issues to solve.

An Advanced Web Application to Manage Daily Improvements on the Shop Floor.

Simplicity for the Shop Floor

FactoryKPI, being valuable smart factory software, allows your team to use it effortlessly because of its structured UI/UX. Factory KPI gives you the control to design and manage daily tracking the way you want. Learn to use Factory KPI in less than 15 mins.

Data to Knowledge : Why is a Software better than Whiteboards / Paper

All the hard work you have done to solve problems, all the root causes and solutions you have executed, can be saved when you transition to digital software in factory. This is valuable knowledge that belongs to your organization and it can be used in future to solve or prevent similar problems. Factory KPI gives you the ability to go back as far as you want to quickly review past data. If you add the optional AI ( artificial intelligence ) option, you also get quick insights and assistance from the AI engine.

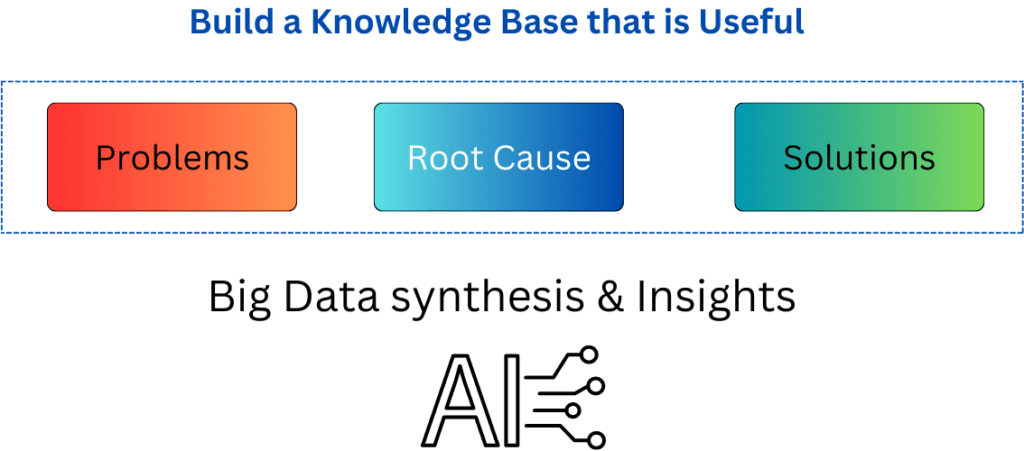

Artificial Intelligence

Our manufacturing software is at the forefront of AI integration, leveraging advanced technologies such as Large Language Models (LLMs) and Natural Language Processing (NLP) to transform how data is interacted with and analyzed on the shop floor. With optional AI capabilities, users can input data and soon engage in natural language conversations with our software. This AI-driven interface supports real-time querying and deep analysis, providing tailored insights through an intuitive, conversational user experience.

Our structured problem solving software for factories plays a crucial role in capturing and analyzing experience based knowledge from retiring employees, preserving essential insights and techniques. This structured knowledge is then made accessible to new staff, ensuring continuity and maintaining operational excellence as workforce demographics evolve. Choose our AI-enhanced manufacturing software for a safe, reliable, and insightful addition to your operational toolkit, ensuring that your shop floor remains innovative and competitive.

Pricing

Standard

$349 /Month

Standard plan gives you all features for managing daily operations and continuous improvement for your shop floor teams. Learning time < 15 mins.

Get a demoFeatures:

- Select your metric to track

- Multiple Departments

- Role based access control

- Access from anywhere

- Responsive for most screens

- Control your own columns structure

- Select and name symbol legends

- Unlimited users

AI (Artificial Intelligence)

Get a quote

All Standard features included. Artificial Intelligence large language model integrated, for fast insights and analysis.

Get a demoFeatures:

- All Standard Features included.

- Data synthesis and analysis with AI.

- Chat with AI and ask any questions regarding the data, comments or any information you have saved in the dashboard.

- Analyze data seperatly for different departments or shifts.

Customized / Enterprise

Get a quote

Customized version as per your needs and specific plant use case. Enterprise deployment as per your requirements.

Get a demoFeatures:

- Customized Features.

- Customized deployment - your on premise server or your preferred company cloud, or a hybrid model.

- We work with you to understand your objectives, design and develop the software as per your needs.

- Talk to us about enterprise solution, for multiple plants / locations / changes in user management or any other requirements.

Choose the Deployment Options based on your Company Policies

ORCA LEAN Standard AWS Deployment

Deploy in your Company's On Premise Server

Deployment in your Company's Cloud

We understand and respect the fact that every plant has different challenges, organizational structure and culture. We will work with you to understand your requirements and customize FactoryKPI to best fit your needs. It is our goal to help you in your improvement initiatives for successful results.

Software Solutions for Manufacturing Excellence

Company

Social

Our Contact Info:

Email: contact@orcalean.com

Phone Number: 248 938 0375

Our Offices