Executive & Strategy

FactoryKPI Executive

KPI Dashboard with Multi-plant analytics and comparisons

Problem Solving

SolvoNext-PDCA

A Smarter Problem Solving and Project Management Software based on deming and Toyota's PDCA - Plan, Do, Check, Act Method.

Qualitygram

A Unique Mobile and Web Software that helps Manage and Solve Problems Faster with Improved Team Communication.

SolvoNext-NCR CAPA

Digitize your NCR & CAPA process and Reduce Cost of Poor Quality (COPQ).

Hoshin Kanri and Gemba Walks: Toyota’s Blueprint for Seamless Communication and Continuous Improvement

March 3, 2025

Toyota’s approach to operational excellence is deeply rooted in communication practices that ensure alignment from top-level strategy to frontline execution. Two critical methodologies—Hoshin Kanri (Policy Deployment) and Gemba Walks—play a crucial role in ensuring that company-wide goals translate into meaningful actions on the shop floor. Along with Yokoten (Best Practice Sharing), these communication strategies create a highly responsive, efficient, and adaptable manufacturing environment.

This blog explores how Toyota uses these methods effectively, breaking down their real-world applications and challenges while offering insights for manufacturers looking to implement them.

Hoshin Kanri: Strategic Goals Aligned with Shop-Floor Execution

Hoshin Kanri, or Policy Deployment, is Toyota’s way of ensuring that company-wide objectives translate into measurable actions across all levels. It’s not just a goal-setting exercise but an interactive process where top management, middle management, and frontline teams collaborate to define, refine, and execute strategies.

How It Works in Reality?

- Setting Strategic Goals: Executive leadership identifies 3-5 critical objectives based on market conditions, customer expectations, and internal capabilities.

- Catchball Process: Unlike traditional top-down directives, Toyota uses an iterative communication process where objectives are discussed with mid-level managers and supervisors. Adjustments are made based on their insights, ensuring goals are both challenging and realistic.

- Cascading Objectives to the Shop Floor: Once refined, objectives are broken down into specific, actionable tasks for each department and worker.

- Regular Review and Adjustment: Toyota reviews progress weekly and monthly. If a strategy isn’t working, they modify the approach instead of waiting until year-end.

Logic Behind this

- Prevents goal misalignment between leadership and shop-floor execution.

- Encourages buy-in from employees since they are involved in defining and refining goals.

- Enables quick corrective actions when market conditions or operational realities change.

The Challenge of True Hoshin Kanri

Many manufacturers struggle with Policy Deployment due to:

- Top-down goal-setting without worker involvement, leading to unrealistic expectations.

- Lack of clear KPIs that make it difficult to measure progress.

- Infrequent follow-ups, causing goals to be forgotten until year-end.

Toyota prevents these pitfalls by making Hoshin Kanri a daily operational discipline rather than an annual exercise. Every worker understands how their tasks contribute to long-term goals through visual management boards, regular team huddles, and cross-functional collaboration.

Gemba Walks: Leadership Engaged in Real-Time Problem Solving

Unlike traditional management audits, Toyota’s Gemba Walks are structured visits where leaders observe, ask questions, and engage with workers to identify process inefficiencies. Gemba Walks are not about policing—they are about supporting employees in problem-solving.

What Toyota Does Differently

- Not Just Presence, but Purpose: Managers don’t walk the floor randomly. They focus on specific problem areas and ask structured questions.

- Active Listening: Employees are encouraged to discuss challenges openly rather than fear repercussions.

- Immediate Problem Escalation: Issues identified are escalated instantly through a structured system involving team leaders, supervisors, and plant managers.

- Data-Driven Walks: Toyota’s managers use real-time production data to decide which areas need attention.

Example of a Gemba Walk in Action

A Toyota plant observed that workers frequently stopped production to manually adjust fixtures. Instead of forcing them to maintain the pace, the manager stopped the line, analyzed the issue, and redesigned the fixture to eliminate the need for manual intervention. This change improved productivity without placing undue stress on workers.

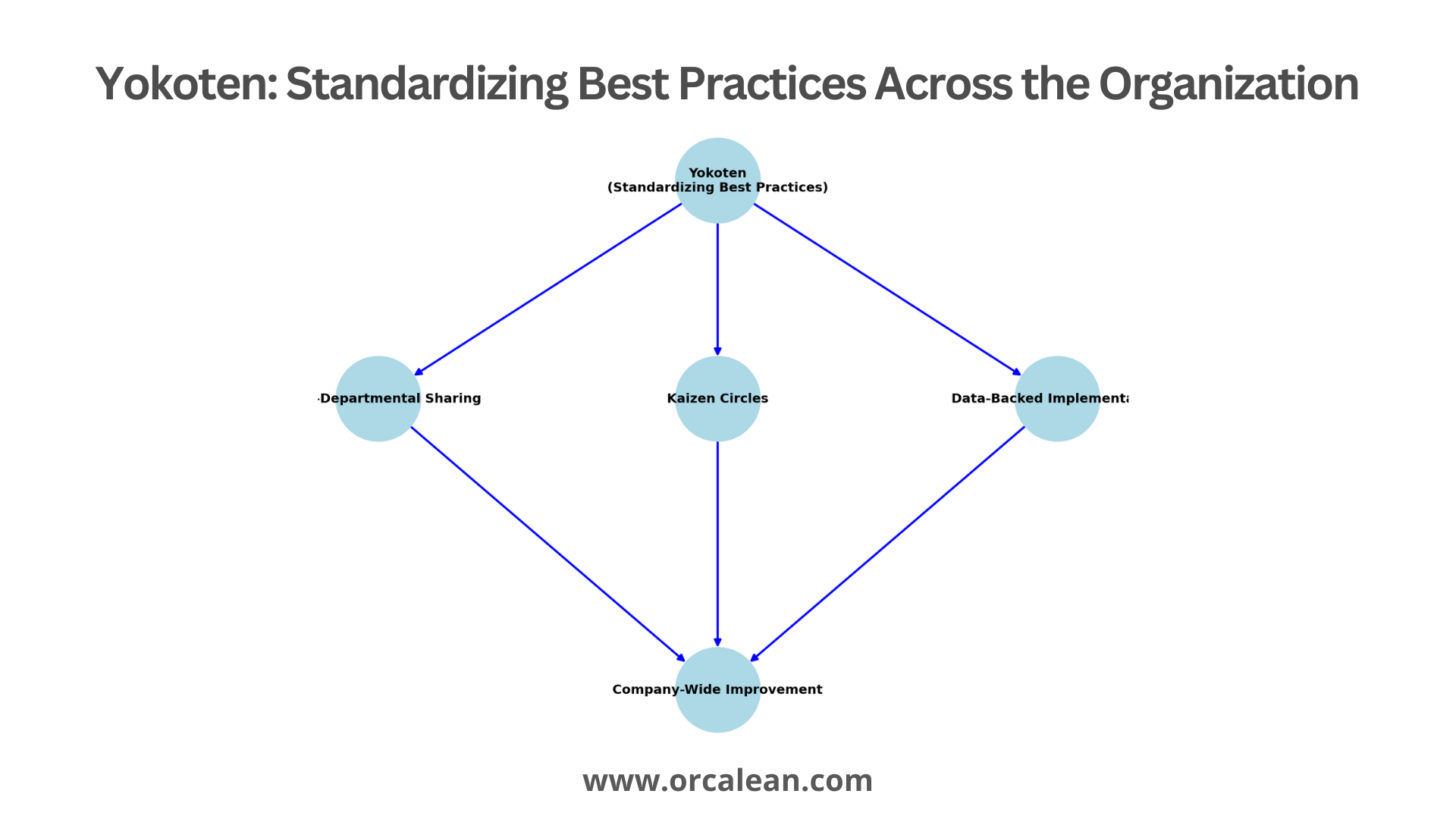

Yokoten: Standardizing Best Practices Across the Organization

Toyota’s commitment to continuous improvement isn’t limited to individual teams—it ensures that improvements in one area are shared and standardized company-wide. This practice, called Yokoten, ensures that no one has to “reinvent the wheel” when solving a problem.

How It Works

- Cross-Departmental Sharing: If a plant finds a better way to perform a task, the process is documented and reviewed for broader application.

- Kaizen Circles: Employees across different locations meet to discuss ongoing improvements and their potential scalability.

- Data-Backed Implementation: Before rolling out a best practice, Toyota ensures that the improvement is backed by quantitative data.

Example: Yokoten in Action

A Toyota plant in Japan improved defect detection using a new camera-based inspection method. Instead of limiting this innovation to a single facility, Toyota’s Yokoten system shared it across multiple plants, reducing defects by 40% company-wide.

Toyota’s Escalation Strategy: Addressing Problems Before They Escalate

Toyota ensures that issues identified during Gemba Walks or Yokoten are addressed immediately through a well-structured escalation hierarchy.

How an Issue Moves Up the Chain

- Team Member → Team Leader: A worker identifies a potential problem, such as abnormal machine vibrations.

- Team Leader → Supervisor: If unresolved, the team leader escalates the issue formally.

- Supervisor → Plant Manager: If systemic, the issue is addressed at the plant level.

- Plant Manager → Corporate Leadership: If it requires design or policy changes, it moves up to higher management.

Example: Escalation in Action

A supplier faced recurring machining tolerance issues in a batch of engine components. Through a Gemba Walk, team members identified inconsistencies in machine calibration. The issue was escalated to the engineering team, which adjusted the manufacturing process. Within two weeks, defect rates dropped by 60%.

Conclusion

Toyota’s success is deeply rooted in its ability to align strategic objectives with on-the-ground execution. Hoshin Kanri ensures that high-level goals are cascaded effectively across all levels, while Gemba Walks keep management actively engaged in real-time problem-solving. The integration of Yokoten further strengthens Toyota’s approach by facilitating the seamless transfer of best practices across teams and locations.

For manufacturers looking to replicate Toyota’s excellence, the key lies in fostering a culture of transparency, accountability, and continuous improvement. By implementing these communication strategies effectively, businesses can achieve enhanced efficiency, reduced defects, and sustained growth in an increasingly competitive landscape.

Software Solutions for Manufacturing Excellence

Company

Social

Our Contact Info:

Email: contact@orcalean.com

Phone Number: 248 938 0375

Our Offices