Executive & Strategy

FactoryKPI Executive

KPI Dashboard with Multi-plant analytics and comparisons

Problem Solving

SolvoNext-PDCA

A Smarter Problem Solving and Project Management Software based on deming and Toyota's PDCA - Plan, Do, Check, Act Method.

Qualitygram

A Unique Mobile and Web Software that helps Manage and Solve Problems Faster with Improved Team Communication.

SolvoNext-NCR CAPA

Digitize your NCR & CAPA process and Reduce Cost of Poor Quality (COPQ).

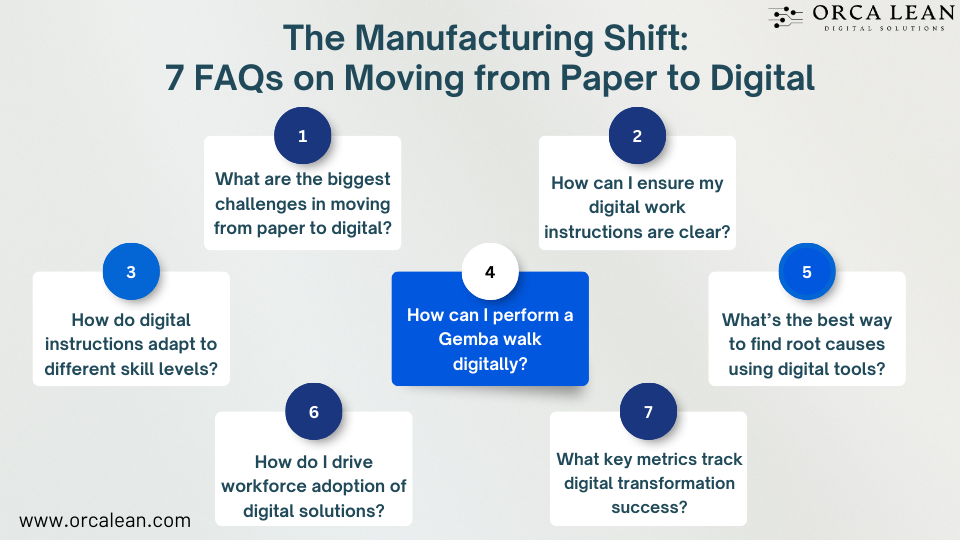

7 FAQs About Transitioning from Paper to Digital in Manufacturing

March 20, 2025

Manufacturing has long relied on paper-based processes for work instructions, quality control, and operational management. However, as industry demands for efficiency, agility, and accuracy increase, paper systems are becoming obsolete. Digital transformation offers real-time insights, reduced errors, and streamlined workflows, yet many executives hesitate due to concerns about cost, complexity, and adoption.

In this blog, we address the top concerns that CEOs, VPs, and manufacturing leaders have about shifting from paper to digital. By answering these critical questions, we provide actionable insights that make the transition smoother and more effective.

1. What Are the Biggest Challenges of Transitioning from Paper to Digital Work Instructions, and How Can They Be Avoided?

The biggest fear businesses face is adoption of cost effective solutions by their team. Some businesses face worker turnover. Thus, it is essential to be aware of those issues when it comes to transition from paper to digital in manufacturing.

- Resistance to change – Employees accustomed to paper may push back. They may fear job insecurity, struggle with technology adoption, or distrust the effectiveness of digital systems.

- Integration with existing systems – Many manufacturers use legacy software that may not easily integrate with new digital tools, leading to potential data silos and operational inefficiencies.

Solution: A phased transition with structured training and change management ensures employee buy-in. Communicating the benefits, offering hands-on workshops, and addressing employee concerns early fosters acceptance.

Additionally, a pilot program helps iron out integration issues before full-scale deployment, ensuring compatibility with existing systems and seamless adoption.

2. How Can I Ensure My Digital Work Instructions Are Clear Before Rolling Them Out?

Unclear work instructions result in costly errors, quality defects, production delays, and frustrated employees. A confusing digital interface or ambiguous instructions can lead to increased rework, scrap, and inefficiencies.

Testing methods:

- Controlled pilot runs with operators – Test digital work instructions in a small production setting with real users. Observe their reactions and identify potential confusion.

- Video recordings for self-review – Have operators record their use of digital instructions to pinpoint areas where they hesitate or misinterpret tasks.

- Digital feedback loops for instant operator input – Use digital systems that allow workers to comment on instructions in real time, helping to refine clarity.

A feedback-driven digital system allows continuous improvement. By gathering insights from frontline workers, manufacturers can refine instructions before full deployment, ensuring efficiency and accuracy from day one.

To learn more in detail, how to create clear work instructions to reduce human error, read our blog. The blog has covered strategies that help you ensure operational efficiency.

3. How Can Digital Work Instructions Adapt to Different User Skill Levels?

Traditional work instructions often follow a one-size-fits-all approach, making it difficult for both new and experienced workers to follow efficiently. This leads to inconsistencies in execution.

Personalized learning paths with digital tools:

- AI-assisted adaptability – Systems can adjust instructions based on user behavior, offering more detailed guidance for beginners and streamlined versions for experts.

- Role-based content visibility – Work instructions can be customized based on an operator’s skill level, ensuring they see relevant details.

- Interactive media – Video tutorials, animations, and AR-based guidance enhance comprehension and reduce training time.

By using digital platforms that offer adaptive learning, manufacturers ensure that employees at all levels perform tasks efficiently and correctly.

4. How Can I Perform a Gemba Walk Digitally?

Traditional Gemba walks require physically walking the shop floor, taking notes, and manually analyzing issues, which can be time-consuming and ineffective.

Digital alternatives:

- Remote monitoring tools – Dashboards provide live shop floor data, enabling managers to assess processes without being physically present.

- Digital note-taking & voice recognition – Leaders can log observations instantly through mobile devices, eliminating the need for handwritten notes.

- Automated alerts – AI-driven anomaly detection flags inefficiencies or safety concerns in real time, making problem identification more proactive.

A digital Gemba walk enhances real-time decision-making and streamlines improvement initiatives, allowing leaders to focus on strategy rather than manual documentation.

5. What’s the Best Way to Identify the Root Cause of Problems Using Digital Solutions?

Root cause analysis (RCA) is often slowed down by fragmented paper records and delayed data access. Finding patterns manually is inefficient and prone to errors.

Digital solutions for RCA:

- Real-time issue tracking with automated logging – Digital systems capture every deviation and record it for traceability.

- AI-assisted pattern recognition – While not the primary focus, AI can analyze historical data and detect recurring failure patterns.

- Digital Ishikawa (fishbone) diagrams and Pareto charts – Structured visualization tools help teams quickly identify and address key root causes.

With digital RCA, manufacturers accelerate problem resolution, improve first-time fix rates, and enhance process reliability.

6. How Can I Ensure My Workforce Adopts Digital Solutions Effectively?

The success of any digital transition depends on employee adoption. Workers often fear that digital tools will complicate their tasks or replace their jobs.

Best strategies for digital acceptance:

- Involve employees in solution selection – Get operator feedback during the evaluation phase to ensure buy-in.

- Make it easier than their current workflow – The digital solution should streamline tasks, not add complexity.

- Provide structured training with real-world applications – Hands-on training ensures workers understand how digital tools improve their work.

- Implement gamification to drive engagement – Reward systems and friendly competitions encourage participation and skill-building.

A well-planned change management approach ensures that employees feel empowered rather than threatened by digital transformation.

7. What Are the Key Metrics to Track for a Successful Digital Transformation?

Simply digitizing paper-based processes in manufacturing isn’t enough. Measuring impact ensures continuous improvement and ROI.

Key metrics:

- Reduction in errors and rework – Measures improvements in process accuracy.

- Cycle time improvements – Tracks efficiency gains from digital workflows.

- Compliance adherence and audit trails – Ensures digital records meet regulatory requirements.

- Operator engagement and feedback loops – Evaluates workforce adoption and satisfaction.

Tracking the right KPIs allows manufacturers to refine digital initiatives, ensuring they deliver tangible business results.

Conclusion: The Future of Digital Manufacturing Is Now

Shifting from paper-based to digital processes is no longer an option—it’s a necessity for staying competitive in today’s fast-paced manufacturing landscape. Standard Work Pro provides a structured, scalable, and intuitive platform to help manufacturers achieve consistency, efficiency, and compliance through digital work instructions and process management.

By implementing Standard Work Pro, manufacturers can ensure faster adoption, reduced errors, and increased workforce engagement. The future of digital manufacturing lies in standardized, adaptive, and data-driven workflows—and Standard Work Pro is the key to making that future a reality. Are you ready to elevate your operations?

Contact us today to learn how Standard Work Pro can transform your manufacturing processes.

Software Solutions for Manufacturing Excellence

Company

Social

Our Contact Info:

Email: contact@orcalean.com

Phone Number: 248 938 0375

Our Offices