Executive & Strategy

FactoryKPI Executive

KPI Dashboard with Multi-plant analytics and comparisons

Problem Solving

SolvoNext-PDCA

A Smarter Problem Solving and Project Management Software based on deming and Toyota's PDCA - Plan, Do, Check, Act Method.

Qualitygram

A Unique Mobile and Web Software that helps Manage and Solve Problems Faster with Improved Team Communication.

SolvoNext-NCR CAPA

Digitize your NCR & CAPA process and Reduce Cost of Poor Quality (COPQ).

30 Manufacturing KPIs You Need to Track to Elevate Performance (Part 1)

April 16, 2025

Manufacturing leaders know that the path to success is paved with data-backed decisions. By carefully monitoring the right Key Performance Indicators (KPIs), organizations can pinpoint areas for improvement, reduce costs, optimize resources, and accelerate overall productivity. Here are 30 critical manufacturing KPIs—organized by category—that every operations manager should keep on their radar.

What Is a Manufacturing KPI?

A manufacturing Key Performance Indicator (KPI) is a key metric that quantifies the efficiency and quality of a production process. By measuring both individual process steps and departmental performance, KPIs highlight where value is generated and where improvement is needed.

In addition to assessing productivity and efficiency, these KPIs also monitor financial performance and workforce factors—crucial elements in Lean manufacturing. Because they have a direct impact on product quality, resource allocation, and overall profitability, manufacturing KPIs are vital for strengthening competitiveness in the marketplace.

Why Use Manufacturing-Specific KPIs?

In a manufacturing environment, tracking the right KPIs is indispensable for maintaining robust operations and steady growth. These metrics empower managers to monitor machine performance, optimize production costs, improve capacity utilization, and even minimize environmental impact.

Manufacturing KPIs not only offer insights into the current state of production—they also serve as a roadmap to guide operational decisions, refine processes, and boost the bottom line. Among the main benefits are:

- Resource Optimization: Minimize material waste and better utilize production capacity.

- Predictive Maintenance: Identify potential breakdowns in advance by analyzing equipment data.

- Waste Reduction: Detects and eliminates sources of loss (e.g., slow cycles, defects, downtime).

- Increased Yield: Achieve higher production outputs without compromising quality.

- Higher Revenue: Greater operational efficiency typically translates into more sales.

- Strategic Alignment: Synchronize production performance with broader business goals.

Let’s discuss the Manufacturing KPIs in detail:

Productivity Indicators

Throughput -

Throughput tracks how many finished units you produce within a certain timeframe. It’s a straightforward measure of production efficiency, helping you quickly spot slowdowns, bottlenecks, and performance dips.

Formula:

Cycle Time -

Cycle time measures the total length of time taken to create a product, covering all processes from start to finish (including processing, waiting, and transfer between stages). By identifying how long each production phase takes, you can spot bottlenecks and refine workflows.

Many production managers have confusion between Cycle time and Takt time and if you also want to explore the difference between Cycle time & Takt Time, read our blog.

Formula:

Production Attainment -

Production attainment shows how closely your actual output matches the planned goal for a given period. This KPI reveals whether you’re meeting, exceeding, or falling short of targets, making it easier to adjust future plans or resources.

Formula:

Overall Equipment Effectiveness (OEE) -

OEE measures how effectively a piece of equipment performs during the time it’s scheduled to run. It zeroes in on unplanned downtime, slow cycles, and defect losses, highlighting the machine’s true performance within its expected operating window.

Formula:

Takt Time -

Takt Time specifies the rate at which products must be manufactured to meet customer demand on time, without over- or underproduction. It does not represent how long it currently takes you to produce one unit; rather, it is the target rhythm.

Formula:

Overall Operating Efficiency (OOE) -

Unlike OEE (which focuses mainly on equipment), OOE paints a broader picture by evaluating the efficiency of all production factors—human resources, materials, and energy. Essentially, it indicates how well a facility transforms inputs into finished goods.

Formula:

Capacity Utilization Rate -

This KPI compares how much of your total production capacity is actually used versus what you could theoretically achieve. It’s crucial for balancing resources and optimizing output without overstretching machinery or personnel.

Formula:

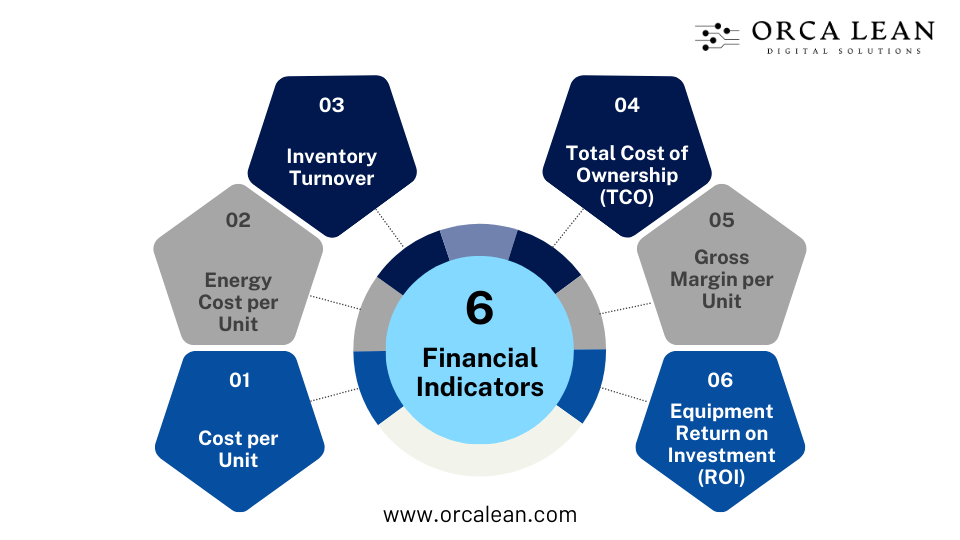

Financial Indicators

Cost per Unit -

Cost per unit calculates the total expense of producing one item. It factors in materials, labor, overhead, and more—helping you see how each piece affects profitability.

If you want to explore how to reduce manufacturing cost with proven strategies, explore our detailed blog. The blog also covers 5 strategies.

Formula:

Energy Cost per Unit -

Energy cost per unit reveals how much you’re spending on power for each item you produce. Keeping this in check can reduce operating costs and bolster profit margins.

Formula:

Inventory Turnover -

Inventory turnover assesses how often you convert stock into sales over a given period. A higher turnover usually indicates streamlined operations, while a low turnover might suggest overstocking or sluggish demand.

Formula:

Total Cost of Ownership (TCO) -

TCO takes a holistic look at the full cost of owning and operating equipment or products over their lifetime—from the initial purchase through maintenance, operation, and disposal. It’s vital for making savvy, long-term investments.

Formula:

Gross Margin per Unit -

Gross margin per unit demonstrates the profit made on each product after direct costs are deducted. Monitoring this KPI can spark pricing and cost-control strategies that improve overall profitability.

Formula:

Equipment Return on Investment (ROI) -

Equipment ROI measures the gains you reap from a piece of machinery compared to the total cost of acquiring and running it. Use this insight to decide whether to buy new equipment, upgrade, or maintain existing assets.

Formula:

These 13 KPIs only scratch the surface of how metrics can significantly transform your manufacturing operations. In our upcoming blog post, we will delve into the remaining 17 indicators that can elevate your productivity, efficiency, and sustainability strategies. Stay tuned, and consider subscribing to our blog for timely updates on the latest best practices, innovative solutions, and performance.

How Solvonext Can Take Your Manufacturing to the Next Level?

Solvonext’s cutting-edge platform enables you to track, analyze, and refine your manufacturing processes in real time. Instead of juggling spreadsheets or disconnected systems, Solvonext brings all your KPIs—throughput, cycle time, overall equipment effectiveness, and more—into one unified dashboard for factories. This centralized view helps you spot inefficiencies, anticipate equipment downtime, and confidently scale operations.

By leveraging advanced analytics and intuitive reporting features, teams across various departments can collaborate seamlessly on continuous improvement initiatives. If you’re aiming for greater profitability, resource optimization, and environmental responsibility, Solvonext is the all-in-one solution that ensures your manufacturing processes run like a well-oiled machine.

Software Solutions for Manufacturing Excellence

Company

Social

Our Contact Info:

Email: contact@orcalean.com

Phone Number: 248 938 0375

Our Offices