10 Benefits of Standard Work for Lean Manufacturing

August 29, 2024

In lean manufacturing, consistency and clarity are key to driving sustained performance. That’s where standard work comes in—a documented, repeatable method for completing tasks in the most efficient and safe way. It outlines the sequence, timing, and expected outcome of every activity on the shop floor.

More than just documentation, standard work is the backbone of Lean. It helps stabilize processes, reduce variability, and lay the groundwork for continuous improvement. Without it, Lean tools like Kaizen, 5S, or JIT lose their power.

In this blog, we’ll explore the 10 major benefits of standard work and why every high-performing U.S. manufacturer should prioritize it—especially when paired with the right standard work instruction software.

What is Standard Work?

Standard work is the foundation of Lean operations. It defines the best-known method for performing a task, incorporating three critical elements: task sequence, takt time, and standard inventory. Together, they ensure every operator performs work the same way, every time—regardless of shift or location.

In practice, standard work aligns closely with concepts like Just-in-Time (JIT) and Kaizen. JIT depends on predictable, repeatable output, which standard work enables. Meanwhile, Kaizen relies on improving existing standards—and without a baseline, improvement is guesswork.

Whether it's reducing errors, cutting down cycle time, or training new workers, standard work brings structure to the chaos of daily operations.

However, paper-based SOPs often become outdated or ignored. That’s where digital standard work instruction tools like Standard Work Pro help. These tools enable easy version control, multimedia guidance, and real-time updates—ensuring your manufacturing software supports the rhythm of continuous improvement.

Real-Life Example of Standard Work

Imagine you're hosting a large dinner party. To ensure the meal is ready on time and delicious, you follow a specific set of recipes with steps that guide you on when to start cooking, which ingredients to prepare first, and how dishes should be served. By following these standardized procedures in manufacturing, you avoid chaos in the kitchen, minimize food waste, and ensure each dish meets your guests' expectations.

Key Components of Standard Work

Here are the key components that make up standard work:

- Takt Time: Takt time is essentially the heartbeat of a production line, calculated based on customer demand. It defines the maximum amount of time in which a product needs to be produced to meet customer needs. For example, if a factory has to produce 240 units in an 8-hour shift, the takt time would be two minutes per unit. This synchronization ensures that production meets demand without overproduction or delay.

- Work Sequence: This component organizes the specific steps required to complete a task at a workstation, optimizing the flow of operations. It details the most efficient order to execute tasks to minimize motion and waiting time, thus maximizing safety and productivity. For example, in an assembly line, the work sequence ensures that parts are assembled in the same order each time to avoid errors and reduce time spent on each unit.

- Standard In-Process Inventory: This involves defining the exact number and type of components, tools, and materials needed at a workstation. By keeping only the necessary items at hand, it reduces clutter, minimizes movement, and speeds up the production process. For example, a workstation assembling electronic components might only have the essential parts and tools required for that specific task, ensuring quick access and minimal delays.

- Detailed Work Instructions: These are clear, often visual instructions provided to ensure that each task is performed accurately and consistently. They include safety guidelines, quality checks, and precise methods to be followed, making it easy for workers to understand their tasks, even if they are new to the position. For example, a step-by-step guide with pictures might be used to show how to assemble a part correctly, highlighting common mistakes to avoid.

- Time Elements: Each task or element within the work sequence is assigned a specific standard time for completion, which helps in setting the pace of work and benchmarks for performance. It allows management and workers to understand how long tasks should take, facilitating better planning and staffing decisions. For instance, if sealing a package is supposed to take 30 seconds, any significant deviation might indicate a problem or inefficiency that needs addressing.

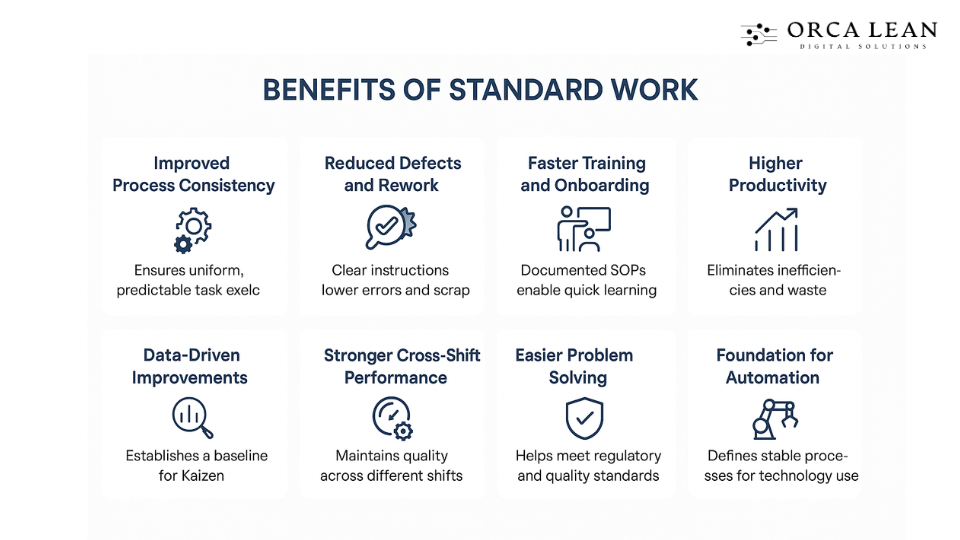

Benefits of Standard Work

1. Improved Process Consistency

Standard work eliminates ambiguity from the production floor by clearly outlining the best-known method for every task. It ensures that all operators perform the job the same way, reducing variations. This leads to predictable output and higher stability in production. Consistency becomes the norm, not the exception.

Example: A U.S. manufacturer using standard work instruction software saw process deviations drop by 30%. Every shift followed the same visual instructions. This improved first-pass yield across all product lines.

2. Reduced Defects and Rework

Defects often arise from tribal knowledge or unclear instructions. With standard work, best practices are documented and followed, reducing reliance on memory. This consistency helps eliminate guesswork, minimizing scrap and rework. Quality improves as every operator follows the same procedure.

Example: A medical device company adopted a digital standard work instruction system. Within two months, rework incidents fell by 25%. Clear visual guides eliminated missteps in assembly.

3. Faster Training and Onboarding

Onboarding new hires becomes quicker and safer when instructions are standardized. Instead of shadowing veterans, trainees can follow clear digital SOPs. Visual work instructions accelerate understanding while reducing errors. Work instruction software makes training consistent across locations.

Example: A fabrication shop implemented standard work software for operator training. New hire ramp-up time reduced from 4 weeks to 2. Supervisors reported fewer basic errors from trainees.

4. Higher Productivity

Standard work highlights the most efficient task sequence and eliminates unnecessary steps. This reduces wasted motion and idle time, making operations smoother. By following optimized workflows, operators complete more work in less time. The result is measurable gains in output.

Example: An electronics firm deployed manufacturing software to streamline SOPs. Standardized tasks raised daily output by 15%. Workers appreciated the reduced complexity in tasks.

5. Data-Driven Improvements

You can’t improve what you haven’t standardized. Standard work provides a baseline for measuring cycle time, takt adherence, and deviations. This structured data allows meaningful Kaizen and PDCA cycles. Standard work instruction software helps track these changes in real-time.

Example: Using digital standard work instruction, a plant logged 160 Kaizen ideas in 3 months. Half were linked to improvements in takt time. PDCA loops became faster and data-backed.

6. Stronger Cross-Shift Performance

Without standard work, performance often drops across shifts. Differences in technique and understanding lead to inconsistent results. With documented SOPs, every shift operates from the same playbook. This ensures quality and pace stay uniform across the day.

Example: After adopting work instruction software, a packaging plant reduced shift handoff errors by 80%. All teams accessed the same SOPs from tablets. Customer complaints due to late deliveries declined.

7. Easier Problem Solving

When problems occur, standard work makes it easier to pinpoint where things went wrong. Deviations from the standard highlight root causes. This clarity accelerates structured RCA using methods like the 5 Whys. Problems are addressed, not just patched.

Example: A team using structured problem-solving software identified a recurring line stoppage. It traced back to a skipped quality check step. The fix was added to the updated standard SOP.

8. Better Compliance and Audit Readiness

Regulatory audits require documentation and traceability. Standard work provides both, ensuring that processes align with ISO, FDA, and IATF standards. With digital standard work instruction, updates and records are centralized and always audit-ready.

Example: A Tier 1 supplier passed an IATF audit with zero findings. They used standard work software to control SOP versions. Auditors praised their real-time documentation system.

9. Enhanced Employee Engagement

Operators aren’t just followers—they’re contributors. Standard work encourages feedback and gives frontline workers ownership in defining best practices. This engagement leads to higher morale and lower turnover. Improvement becomes a team effort.

Example: A plant used standard work instruction software to crowdsource SOP improvements. Over 100 suggestions were implemented in 90 days. Employee satisfaction scores rose significantly.

10. Foundation for Automation

Automation only works if the process is stable. Standard work defines that stability, outlining the exact steps and tolerances. It prepares processes for integration with MES or robotics. Digital tools simplify the transition by mapping manual tasks clearly.

Example: Before adding cobots, a factory digitized their manufacturing standard operating procedures. This cut robot programming time by 40%. Engineers avoided rework and setup errors.

Digital Standard Work: Scaling Benefits Across Teams

Despite its benefits, many manufacturers still rely on paper-based standard work, which comes with serious limitations. Printed SOPs become outdated quickly. Updates may not reach every line. Visual aids are hard to maintain. And in multi-site operations, maintaining consistency becomes nearly impossible.

That’s where digital standard work instruction platforms offer a game-changing solution.

With tools like Standard Work Pro, you can:

- Push real-time updates across teams and sites

- Include videos, images, and checklists in digital work instructions

- Maintain centralized version control for every standard operating procedure (SOP)

- Enable mobile or kiosk access directly on the floor

- Track compliance and operator feedback seamlessly

Whether you're onboarding a new line, scaling to a second plant, or preparing for ISO audits, a standard work software system makes it easier to manage complexity and drive improvement.

By turning static documents into interactive tools, digital solutions future-proof your work instruction software and make continuous improvement scalable.

Conclusion

Standard work is more than a Lean tool—it’s the foundation of operational excellence. It ensures consistency, enhances quality, empowers employees, and creates the structure needed for continuous improvement and automation.

If your factory is still relying on outdated or paper-based instructions, it’s time to evolve.

Audit your current SOPs. Identify inconsistencies. And take the next step toward a more connected, efficient, and compliant operation.

Looking to simplify, scale, and sustain standard work? Try Standard Work Pro—book a free demo today.

Software Solutions for Manufacturing Excellence

Company

Social

Our Contact Info:

Email: contact@orcalean.com

Phone Number: 248 938 0375

Our Offices